Research and innovation for the industrialisation of composites parts

A commitment to continuous improvementInnovation at Techni Modul Engineering is an integral part of our culture and a key to meet and exceed the future requirements of our customers. Each year 10% of our turnover is dedicated to the funding of our R&D programs. Several innovations have been introduced to the market.

In our R&D department, we develop cost-effective and innovative industrialization solutions for composite parts to meet future customer expectations.

Our objective: to develop new products and processes that can increase our customers’ competitiveness but also to assist you in the manufacturing of specimens/prototypes, material testing or process validation.

Our SMART Solutions are the result of years of research and development.

Test centre / R&D: prototyping of composite parts

The prototyping of composite solutions are crucial steps in the ultimate success of your project. The engineering team at Techni-Modul Engineering has been involved in the prototype of a wide variety of composite products over the past three decades that helped us reaching a high level of efficiency.

Our R&D department chooses innovative and current composite processes: Thermoforming, Infusion, RTM, C-RTM, SQRTM.

Our workshop is well equipped with all the means necessary for the manufacture of composite prototypes: presses, robot with frame or suction cups, 450°C IR oven, compaction machine, injection machine, thermal group, vacuum pumps and means of control and regulation..

These means can be rented per day, per week… We can also assist and advise you for:

Feasibility analysis of a part or a type of geometry

- The characterization of a material

- The realization of specimens

- Other on request

By choosing TME as your privileged partner, you are assured of obtaining solutions that will easily integrate into an efficient and competitive mass production environment, while respecting the confidentiality of your project.

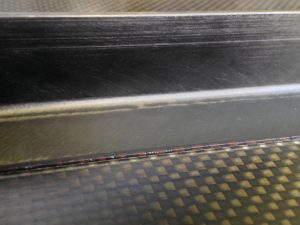

FPTM (SQRTM)

FPTM (Final Pressure Transfer Molding) is a process that enables the fabrication of composite parts in Pre-Preg materials in a closed mold by application of pressure. It is a process been developed by the R&D department of TME.

This is an Out of Autoclave process for the transformation of Prepreg materials.

Our new process is characterized by the fact that the thermoset cycle is realized by injecting simultaneously a gas in the molding cavity through the gas channel.

Collaborative projects

Techni-Modul is also involved in several European projects:

OPTICOMS: research and develop technologies for more affordable composite aero structures with focus on cost effective existing materials and improvement of production technologies for a later full composite wing production.

INNOTOOL 4.0: development of a low-cost, robust and lightweight tooling with an integrated dynamic system for mould temperature control. Such advanced tooling will enable the design and manufacture of highly precise, complex-shaped composite structures.

DEWTECOMP: development of an innovative and efficient induction welding system. The goal is for the system to achieve a structural bond between reinforcement parts (gussets, wedges, fittings) and structural frames.