Kitting for production lines

Optimisation of a complex process for warehouse assembly

Companies must therefore devote significant human resources to this process in order to guarantee optimal quality of the preform.

Our Kitting solutions allow the sorting and kitting of composite materials. They can be fed manually or automatically via one or more cutting systems. With fully reliable cutting, it is possible to automatically pick up the folds on the cutting tables with a robot.

The objective of TME's kitting solutions is to eliminate the risk of human error in this type of application.

Our SMART Control solution can complement our kitting solutions to enable ply recognition. This will allow the robot (in the case of a robotic solution) to take the ply from the conveyor and place it on the sorting table.

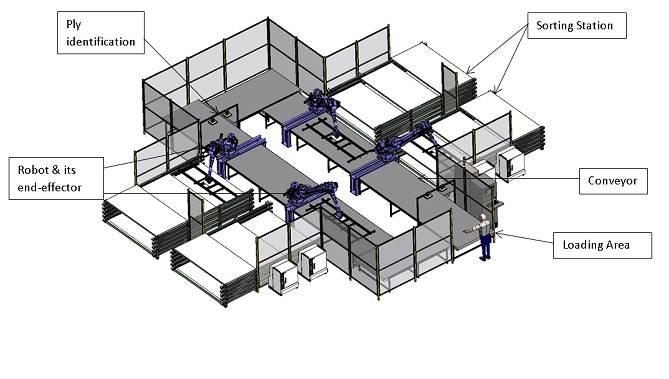

Customised kitting solution:

Cell

Designed according to request. Different configuration possibilities according to requirements.

Configuration example :• Plies loading area

• Robot equipped with gripper

• Ply recognition system (SMART Control)

• Conveyor

• Sorting station(s)

• Supervision system

Standard solution:

SMART Gripper

The SMART Gripper is an universal vacuum gripper tool installed on a mobile system (robotic arm for example).

Characteristics:• Single standardized module (500x300mm)

• Several modules can be combined to handle larger folds

•60 independently controlled suction cups allow you to pick up folds of different sizes and shapes