Objective: Zero defect manufacturing

TME will participate in JEC World 2023 with Composite Alliance Corp.

16 March 2023

New article published in Composites World : “Techni-Modul Engineering grows automated technologies for composite part manufacture”

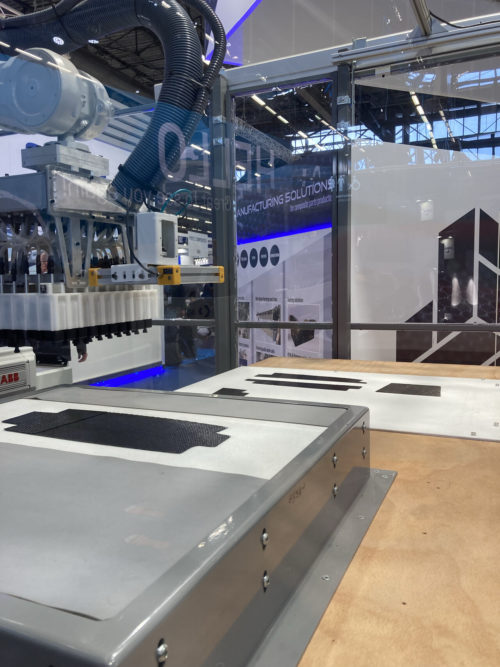

22 May 2023Today’s product requirements are more challenging than ever. New processes and approaches are required especially for kitting, stacking and lay-up of preforms and/or composite parts. SMART Control is an innovative automatic solution bringing AI in the composites lay up control. Its camera system, its lighting and plug & play software allows control functions such as shape identification and recognition, fiber orientation control, ply positioning, gap and/or overlap detection as well as FOD and defect detection on composite materials.

SMART Control guarantees the manufacturing quality, accuracy, repeatability and process times that must meet the need for more and more automation. It was initially developed for the aerospace industry but can also be introduced to any other composites sector in which high-rate kitting, stacking and preform lay-up of UD or woven materials is required such as for aeronautic applications (for class 1 parts).

Key features :

- 100% approved quality,

- Identification and shape recognition (DXF matching),

- Control of fiber orientation with an accuracy of ± 0.3°,

- Control of the plies position with an accuracy of 0.25mm (DXF matching),

- Detection of gaps and/or overlaps between 2 plies of the same layer (DXF matching),

- Detection of FOD > Ø 3mm,

- Recognition of defects on composite materials.

More information here.