Réalisation de kitting pour les chaînes de production

Optimisation d'un processus complexe pour l'assemblage en entrepôt

Les entreprises se doivent de consacrer d’importantes ressources humaines à cet effet afin de garantir une qualité optimale de la préforme.

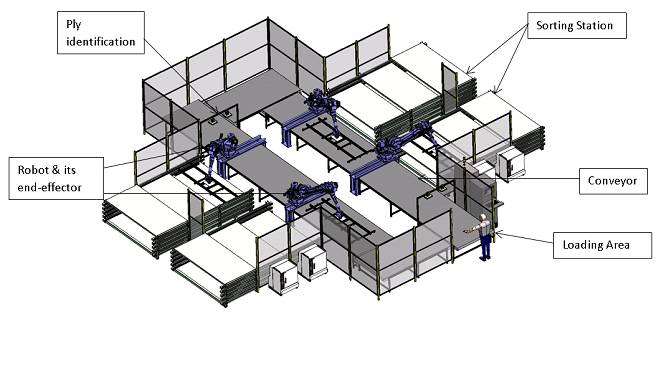

Nos solutions de Kitting permettent le tri et la mise en kits des matériaux composites. Elles peuvent être alimentées manuellement ou automatiquement via un ou plusieurs système de découpe. Avec une découpe totalement fiable, il est possible de prendre automatiquement les plis sur les tables de découpe à l’aide d’un robot industriel.

L’objectif des solutions de kitting de TME est d'éliminer les risques d'erreurs humaines pour ce type d'application.

Notre solution SMART Control peut venir en complément de nos solutions de kitting afin de permettre la reconnaissance des plis. Cela permettra au robot (cas d’une solution robotisée) de prendre le pli sur le convoyeur et de le placer sur la table de tri.

Solution sur mesure de kitting:

Cellule

• Zone de chargement des plis

• Robot équipé d’un gripper

• Système reconnaissance des plis (SMART Control)

• Convoyeur

• Station(s) de triage

• Système de supervision

Solution standard:

SMART Gripper

• Module standardisé unique (500x300mm)

• Plusieurs modules peuvent être combinés afin de traiter des plis de plus grande dimension

• 60 ventouses pilotées indépendamment permettent de prendre des plis de différentes tailles et de différentes formes